PPR pipe is light weight, high temperature resistant. Suitable for hot and chill liquid transportation in all types of construction.

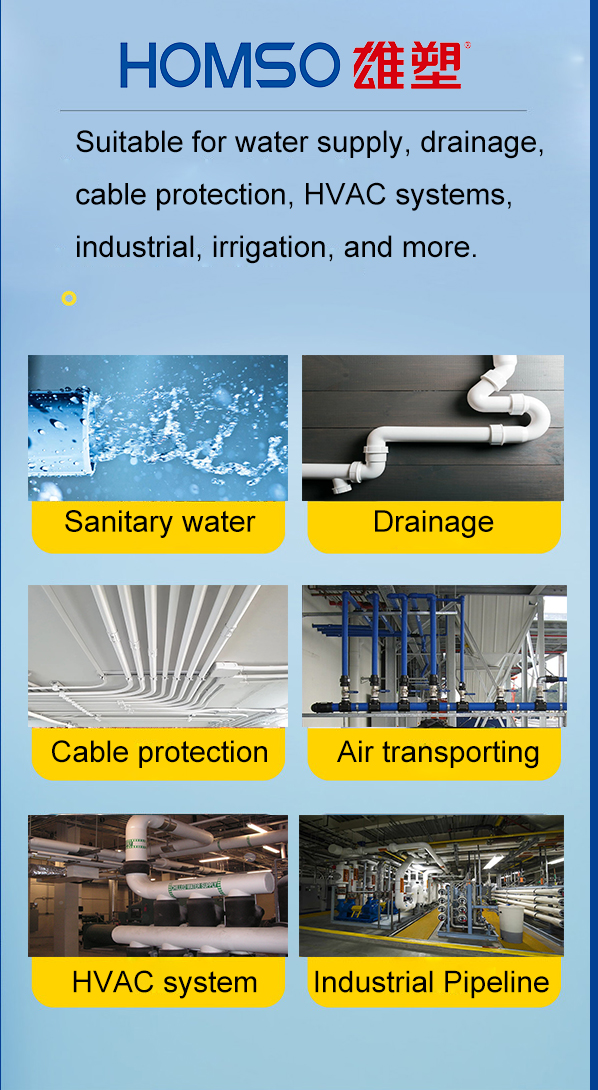

PPR Pipe become more and more popular in daily life and industry:

PPR piping system has following features:

-No corrosion: PPR raw material is superior than metal. The materials can resist bacteria and is stable.

- No scaling: the surface is smooth and the PPR pipe and fitting surface treatment is tear growth resistance.

- Limited heat loss and condensation

- Low noise

- Limited head loss

- Resistance to abrasion

- Resistance to stray currents

- Durability and Lightness: can save maintenance cost and transport cost.

HOMSO PPR piping system types:

- Single layer made of PP-R and PP-RCT materials

- PP-R three layers with a central layer of glass fibers FG and aluminum AL

- PP-RCT three-layer with a central layer of glass fibers FG

Compliance with standards: EN, DIN, BS, ASTM

OEM and ODM: HOMSO also can do customized PPR pipe and fittings, fitting type design, special specification customized and customized logo.

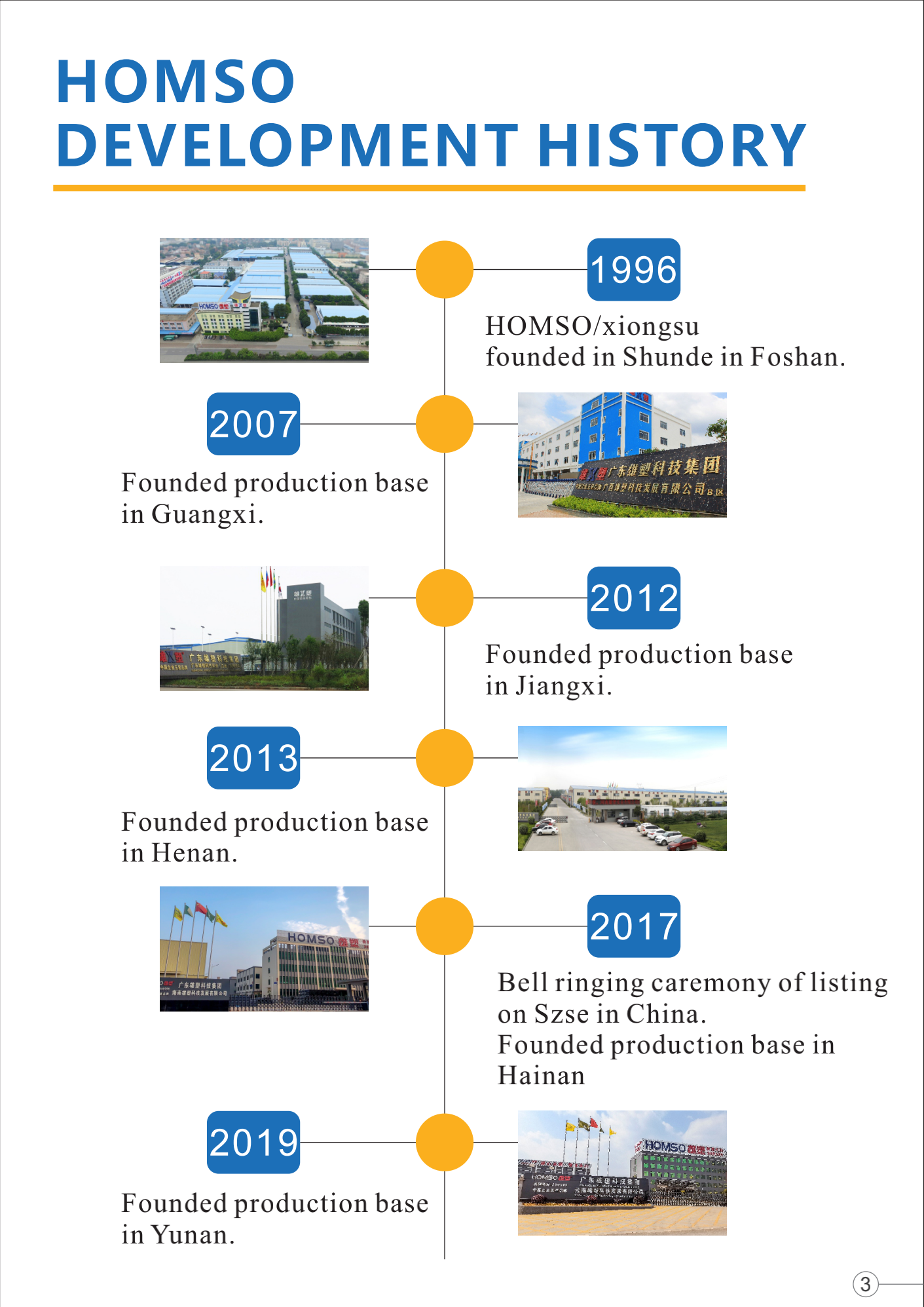

HOMSO has 6 production bases in different provinces. From pipe and fitting moulding design to mouldings processing to finished products transportation, all steps can be completed in HOMSO factory. It's convenient to control product qualilty and production lead time. One-stop service.

HOMSO has over 60000 moulds in factory and owns mould processing machines and professional technians. HOMSO can design and produce many types of thermoplastic pipe and fittings to satisfy different applications.