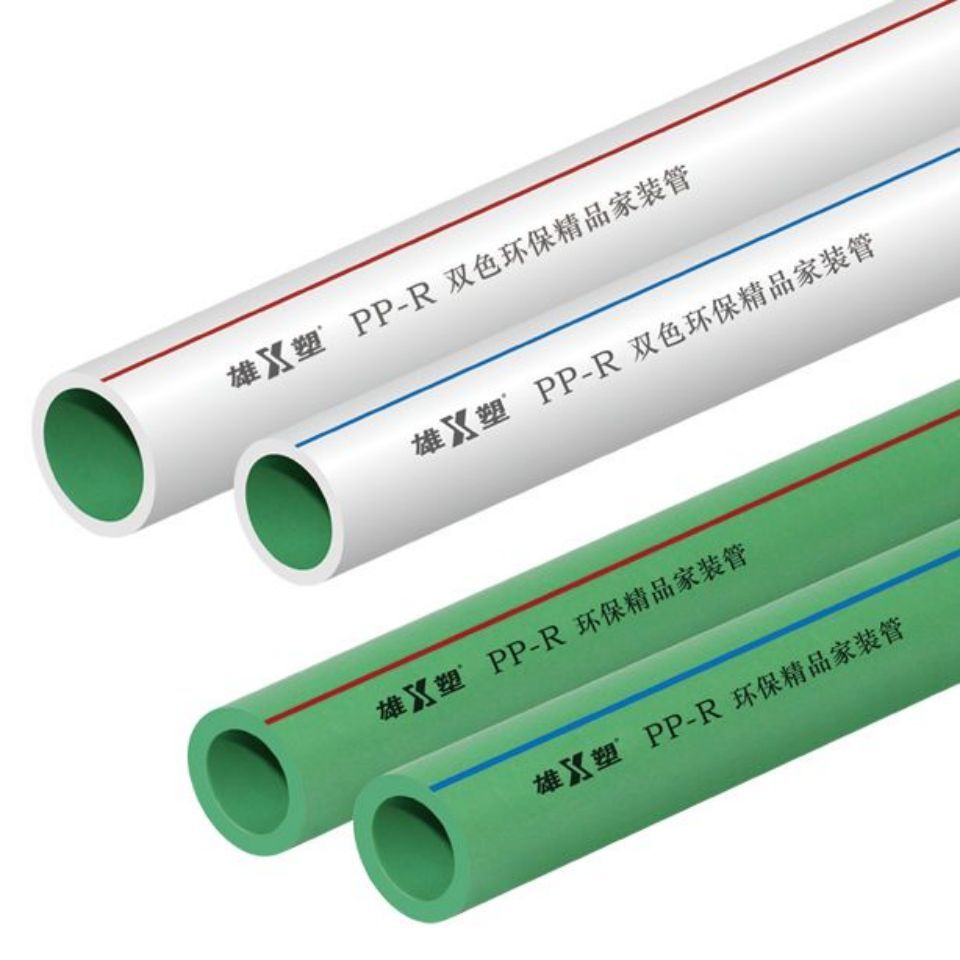

HOMSO PPR pipe and fittings plastic pipe introduction

1、 Definition and Materials

HOMSO PPR pipe and fittings is the abbreviation for Polypropylene Random in English, commonly known as Type 3 polypropylene. HOMSO PPR pipe and fittings are polypropylene pipes produced using random copolymerization technology, which have high strength and rigidity, chemical corrosion resistance, and good processing performance.

2、 Characteristics and advantages

Corrosion resistance: HOMSO PPR pipe and fittingshave excellent chemical corrosion resistance and can resist the corrosion of most chemical substances, such as acid, alkali, salt water, etc., making them suitable for applications in various complex environments.

High temperature resistance: HOMSO PPR pipe and fittings have high temperature resistance and can work stably in high-temperature environments for a long time. The highest temperature resistance can reach 95 ℃, making them suitable for high-temperature applications such as hot water supply systems and solar hot water systems. At the same time, its Vicat softening point is 131.5 ℃, which can transport water flows of -15 ℃~95 ℃ for a long time.

Thermal stability: HOMSO PPR pipe and fittings have excellent thermal stability, are not easily deformed or aged, and will not cause discoloration or fading even after long-term use, maintaining a long service life.

Low noise: HOMSO PPR pipe and fittings have good sound insulation effects and produce less noise during use, making them suitable for places that require a quiet indoor environment, such as residences, hotels, etc.

Easy to install:HOMSO PPR pipe and fittings have a low coefficient of friction and an integrated design, which does not require a large number of accessories during installation and is not easily broken or leaked, saving installation time and costs. At the same time, it adopts hot melt connection technology, which can achieve seamless welding and avoid the risk of water leakage.

Environmental protection and energy conservation: HOMSO PPR pipe and fittings are made of environmentally friendly materials, non-toxic and odorless, harmless to the human body, and will not release harmful substances, meeting hygiene and environmental protection requirements. In addition, its low thermal conductivity avoids the loss of thermal energy and improves energy utilization efficiency.

Impact resistance: HOMSO PPR pipe and fittings have good impact resistance and are not easily broken even under low temperature conditions, with a long service life.

3、 Application Fields

PPR pipes are widely used in construction, municipal, industrial, and agricultural fields due to their excellent performance and wide range of applications, including building water supply and drainage, urban and rural water supply and drainage, urban gas, power, and fiber optic cable sheathing, industrial fluid transportation, agricultural irrigation, etc. Specifically, it includes the following aspects:

Cold and hot water transportation: HOMSO PPR pipe and fittings are ideal pipes for home decoration and urban water supply, with advantages such as safety, hygiene, convenient construction, and long service life.

Natural gas and coal gas transportation: HOMSO PPR pipe and fittings have the characteristics of stable performance and easy construction, making them the preferred pipe materials for transporting natural gas and coal gas.

Food emissions: HOMSO PPR pipe and fittings have the characteristics of long lifespan and low maintenance costs, and are suitable for discharge pipelines in the food industry.

Urban sewage discharge: HOMSO PPR pipe and fittings have a low degree of decay and short construction time, making them suitable for use in urban drainage pipelines.

Electric wiring construction: HOMSO PPR pipe and fittings have excellent insulation performance, compressive strength, and low friction coefficient, making them suitable for electric wiring construction.

4、 Production process and quality inspection

The production process of HOMSO PPR pipe and fittings includes steps such as raw material preparation, extrusion molding, shaping and cooling, hot melt connection, internal and external surface treatment, and quality inspection. Ensuring that the quality of raw materials meets relevant standards is the key to ensuring the performance of the final product. At the same time, strict quality inspection is also indispensable in the production process, including appearance inspection, size measurement, pressure testing and other multiple links, to ensure that every PPR pipe meets product standards and design requirements.

5、 Precautions

High construction technology requirements: The construction of HOMSO PPR pipe and fittings requires the use of specialized tools and professionals to ensure system safety.

Avoid prolonged exposure to sunlight: Although HOMSO PPR pipe and fittings have excellent weather resistance, prolonged exposure to sunlight may accelerate their aging process, so it should be avoided as much as possible.

Regular inspection and maintenance: To ensure the long-term stable operation of HOMSO PPR pipe and fittings, they should be inspected and maintained regularly to promptly identify and address potential issues.

In summary, HOMSO PPR pipe and fittings play an important role in various fields due to their excellent performance and wide application areas. During use, attention should be paid to following relevant regulations and requirements to ensure its safe and reliable operation.

.jpg)